Project Details

Industries:

Services:

Scope & Objectives

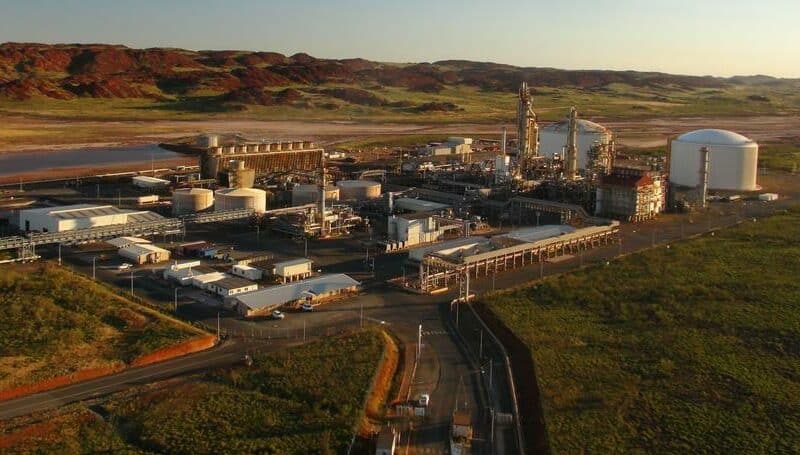

The existing Pluto LNG Train 1 was designed to process Pluto gas, a rich feed gas. Scarborough gas is a biogenic gas with little ethane and only trace amounts of heavier hydrocarbon components. As a result, modifications to the existing Train 1 facilities are required to enable the processing of Scarborough gas in both blended with Pluto gas (Phase 1) and 100% Scarborough gas (Phase 2).

Objectives

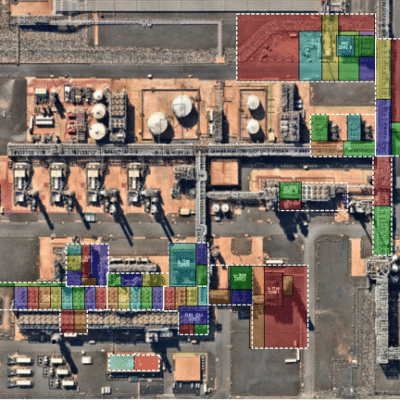

1. Laser scan the designated areas (Figure A) resulting in minimal shadow and the highest relative accuracy.

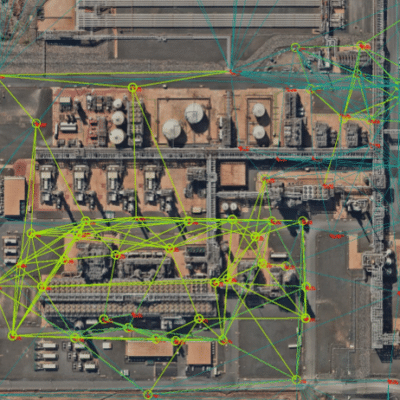

2. Install Additional adjusted control marks as needed.

3. Process data offsite daily in order to provide feedback to surveyors in real time as well as to reduced final delivery timeline.

The Challenge

The Scarborough gas has specific characteristics – little ethane and only trace amounts of heavier hydrocarbon components, requiring a different processing method. Alongside, dealing with biogenic gas, maintaining the highest levels of accuracy in the scans, orchestrating work to assure minimal disturbance, and catering to the clients’ urgency were formidable challenges.

Our Solution

We adopted a strategic approach in our solution. We leveraged our expertise in laser scanning technology whilst simultaneously coordinating 3 scanning crews following a meticulous schedule. A streamlined office processing system segmented the project into manageable parts, allowing different CAD Technicians to work synergistically around the clock, thus ensuring timely delivery, efficiency, and high-quality results.

The Results

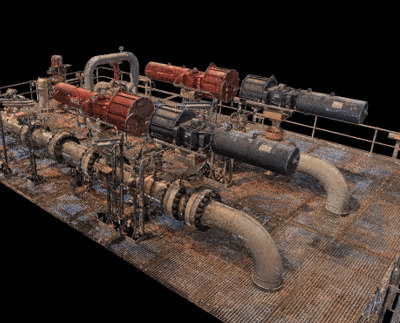

Our 7-week campaign showcased the exceptional capabilities of Handley Surveys through its visible outcomes—highly detailed, accurate 3D models, (refer to the image gallery), efficient project planning, and completion within short timeframe without issue.

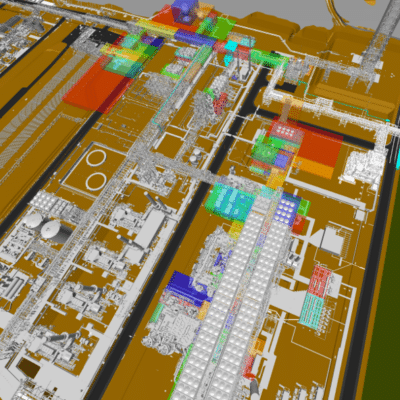

- Efficient Scanning: Over 40 days, we scanned 13 zones, divided into 98 cells. This highlights our ability to handle complex projects efficiently.

- Control Installation: In 10 days, we established a Control Network throughout Train 1 as well as PRS and Spheres, underscoring our proficiency in managing detailed tasks within strict timelines.

We believe in surveying that enhances design and construction processes. Work smarter, not harder, message us now for a better solution.