Laser Scanning

-

Laser Scanning

At Handley Surveys, we understand that you shouldn’t have to choose between speed and accuracy. That’s why we’re providing reliable laser scanning data–driven by advanced technology. Our commitment is to empower your decisions with high quality data. We safeguard this so you can build with genuine confidence.

At every stage of the data capture process, we ensure the highest levels of safety, quality, and performance. Our integrated service model covers each step; from scanning to creating customised reports that meet your specific needs and everything in-between.

-

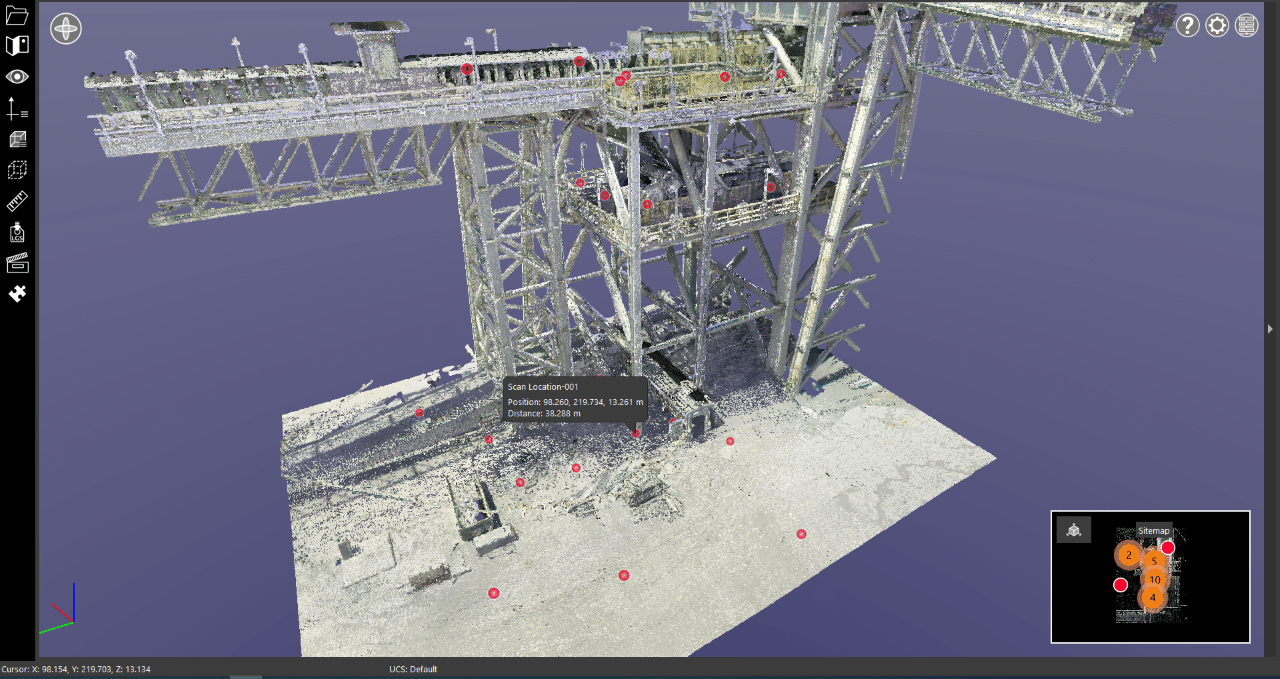

Alignment Surveys

Laser scanning technology is advancing industrial alignment surveys; providing improved accuracy, greater efficiency and holistic safety. It’s an incredibly specialised service for cranes rail, and conveyor equipment that has never been more critical given the dangers associated with system malfunction.

Surveying plays a crucial role. Surveyors collect raw data, validate the accuracy of spatial design, supervise construction, verify compliance, and produce a final spatial model.

-

Clash Detection & Avoidance Surveys

Put simply, clash avoidance is the prevention and clash detection is the treatment, when spatial overlaps occur with structures, objects or equipment in the construction lifecycle. Clash detection is the very backbone of Building Information Modelling (BIM) widespread integration. Our Scan to BIM services provide a common data environment so that everyone can properly visualise the 3D model and make any changes in design more efficiently.

-

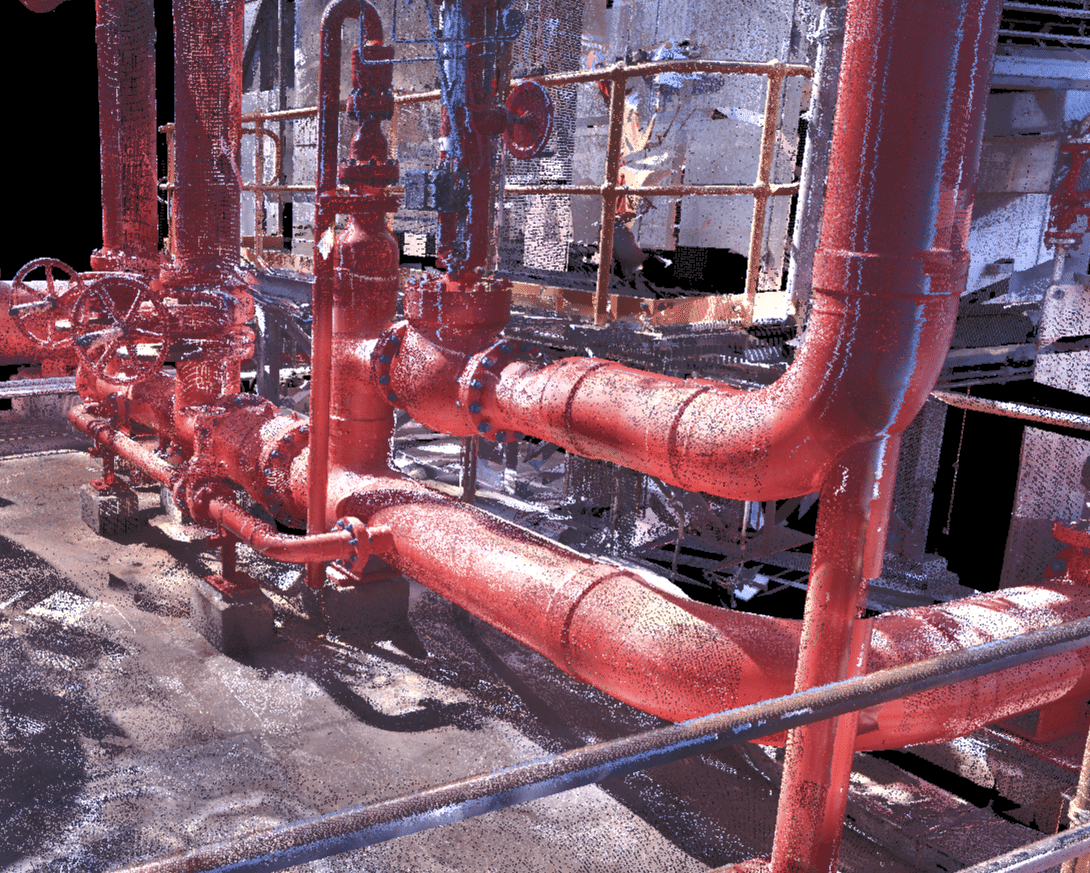

As-Built Surveys

Our advanced laser scanning technology creates detailed 3D models of buildings, including structure, architectural elements, and utility services. This provides valuable information for architects, engineers, and contractors. This can be extremely useful for both pre-project construction planning and post-project quality assurance. It ensures precise documentation and supports informed decision-making.

-

Fabrication Surveys

Laser Scanning is used extensively to help fabricators from the early stages of reporting on deviations from original design, right through to guiding cut lines and monitoring progress. Its ability to design precise jigs makes it an invaluable tool when it comes to producing rapid, accurate, repeatable fabrication outcomes.

-

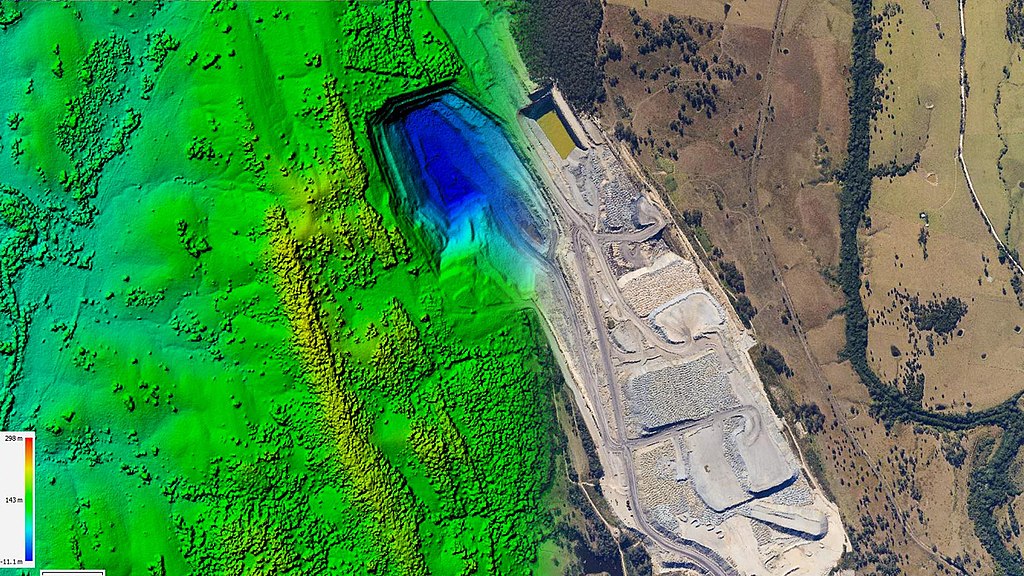

Volumetric Surveys

Laser scanning integration has greatly improved the volumetric survey process, critical for stockpile and inventory management. 3D models enable precise volume calculations, monitoring changes over time, and aiding decision-making. This data ensures efficient resource allocation, accurate planning, and effective execution of stockpile management and bulk earthworks projects.

At Handley Surveys, we understand that you shouldn’t have to choose between speed and accuracy. That’s why we’re providing reliable laser scanning data–driven by advanced technology. Our commitment is to empower your decisions with high quality data. We safeguard this so you can build with genuine confidence.

At every stage of the data capture process, we ensure the highest levels of safety, quality, and performance. Our integrated service model covers each step; from scanning to creating customised reports that meet your specific needs and everything in-between.

Laser scanning technology is advancing industrial alignment surveys; providing improved accuracy, greater efficiency and holistic safety. It’s an incredibly specialised service for cranes rail, and conveyor equipment that has never been more critical given the dangers associated with system malfunction.

Surveying plays a crucial role. Surveyors collect raw data, validate the accuracy of spatial design, supervise construction, verify compliance, and produce a final spatial model.

Put simply, clash avoidance is the prevention and clash detection is the treatment, when spatial overlaps occur with structures, objects or equipment in the construction lifecycle. Clash detection is the very backbone of Building Information Modelling (BIM) widespread integration. Our Scan to BIM services provide a common data environment so that everyone can properly visualise the 3D model and make any changes in design more efficiently.

Our advanced laser scanning technology creates detailed 3D models of buildings, including structure, architectural elements, and utility services. This provides valuable information for architects, engineers, and contractors. This can be extremely useful for both pre-project construction planning and post-project quality assurance. It ensures precise documentation and supports informed decision-making.

Laser Scanning is used extensively to help fabricators from the early stages of reporting on deviations from original design, right through to guiding cut lines and monitoring progress. Its ability to design precise jigs makes it an invaluable tool when it comes to producing rapid, accurate, repeatable fabrication outcomes.

Laser scanning integration has greatly improved the volumetric survey process, critical for stockpile and inventory management. 3D models enable precise volume calculations, monitoring changes over time, and aiding decision-making. This data ensures efficient resource allocation, accurate planning, and effective execution of stockpile management and bulk earthworks projects.